Do GaN Chargers Work with Non-Fast Charging Cables? An Engineering Perspective

03 Feb,2026

03 Feb,2026

In the competitive landscape of power electronics, a high-performance usb type c charger is only as effective as the cable connecting it to the load. For distributors and OEM buyers, understanding the interplay between a sophisticated GaN (Gallium Nitride) charger and a standard (non-fast charging) cable is critical for reducing return rates and ensuring user safety.

The short answer is: Yes, a GaN usb type c charger will work with a non-fast charging cable, but it will automatically restrict power output.

However, "working" and "performing optimized charging" are two very different engineering concepts. As an R&D lead who has overseen the mass production of millions of units, I will break down the handshake protocols, safety trade-offs, and why your choice of charger topology matters even when the user uses an inferior cable.

The Technical Fundamentals: The "Handshake" and E-Markers

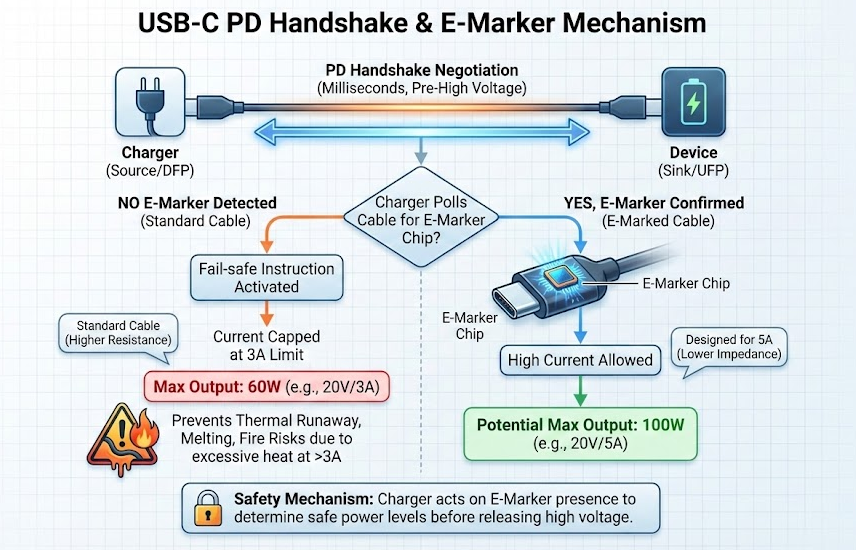

When a user connects a modern usb type c charger to a device, a complex negotiation process—known as the Power Delivery (PD) Handshake—occurs within milliseconds. This happens before any high voltage is released.

The charger operates as the Source (DFP) and the device as the Sink (UFP). The cable acts as the medium, but it is not passive.

Standard Cables (3A Limit): Most generic "non-fast charging" USB-C cables are rated for a maximum of 3 Amps. They lack an "E-marker" chip (Electronic Marker).

The Detection Logic: When the usb type c charger initiates the handshake, it polls the cable. If no E-marker is detected, the charger’s firmware acts on a fail-safe instruction: Cap current at 3A.

Voltage Limitation: Even if the charger can output 100W (20V/5A), without an E-marker confirmation, it will never exceed 60W (20V/3A).

This mechanism prevents thermal runaway. Sending 5A through a cable designed for 3A causes excessive heat generation due to higher contact resistance and conductor impedance, leading to potential melting or fire risks.

Industry Pain Points: The "Slow Charging" Perception

For B2B buyers sourcing usbc chargers, the most common post-sales complaint is "The charger isn't fast enough." In 70% of these cases, our failure analysis reveals the charger is functioning perfectly, but the user is bottlenecked by the cable.

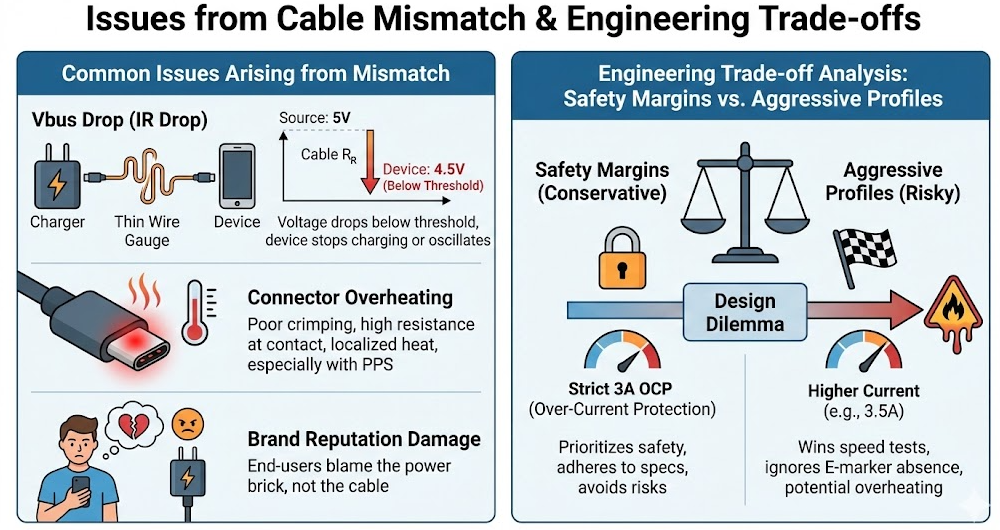

Common issues arising from this mismatch include:

Vbus Drop (IR Drop): Thin wire gauge in cheap cables causes significant voltage drop under load. If the voltage at the device end drops below the acceptable threshold defined in the PD spec, the device may stop charging or oscillate between charging and disconnected states.

Connector Overheating: Non-compliant cables often have poor crimping at the connector head. When a pps charger (Programmable Power Supply) attempts to adjust voltage dynamically, high resistance at the contact point generates localized heat.

Brand Reputation Damage: End-users rarely blame the cable; they blame the power brick.

Engineering Trade-off Analysis: Safety Margins vs. Aggressive Profiles

In power supply design, we face a constant dilemma: How aggressively should we tune the usb type c charger firmware?

Some manufacturers, in an attempt to win "speed tests," design their chargers to ignore the absence of an E-marker or set the Over-Current Protection (OCP) trigger point too high (e.g., allowing 3.5A on a 3A path).

Why this is a dangerous trade-off:

Short-term Gain: The device might charge slightly faster, impressing a reviewer.

Long-term Risk: The cable degrades faster. The increased heat increases the resistance ($R$), which increases power loss ($I^2R$), creating a feedback loop that leads to connector failure.

Our Judgment: A reliable B2B product must prioritize the "Lowest Common Denominator." We rigorously tune our OCP and OVP (Over-Voltage Protection) to assume the user will use the worst possible cable. It is better to charge at 60W safely than to attempt 65W and risk liability. We prioritize long-term reliability over marginal speed benchmarks.

Tommox Design Philosophy: Intelligent Cable Compensation

At Tommox, we address these variances through our "Smart Sense" topology in every usb type c charger we design. We do not just rely on the PD protocol's basic requirements; we implement active monitoring.

Our engineering solution involves:

Dynamic Impedance Monitoring: The controller actively monitors the voltage droop on the Vbus. If the drop is disproportionate to the current delivered (indicating a bad cable), the charger throttles back power before the device requests it.

Thermal Foldback: We place NTC thermistors near the output USB-C receptacle. If the connector heat rises due to a high-resistance cable plug, the system derates output power.

PPS Optimization: For a pps charger, precise voltage steps (20mV) allow us to fine-tune voltage to compensate for minor cable losses (Cable Drop Compensation) without violating safety limits, ensuring the device receives the target voltage.

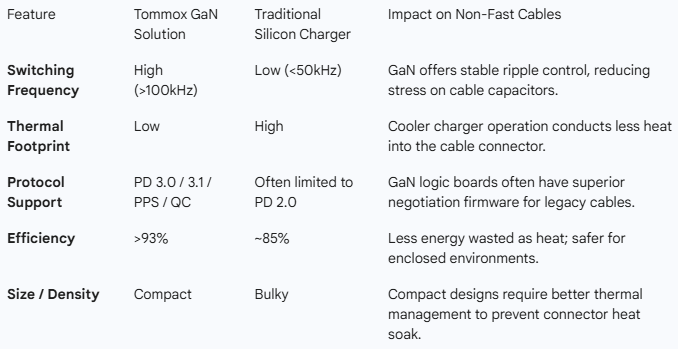

Specification Comparison: GaN vs. Silicon with Legacy Cables

How does a GaN-based usb type c charger compare to traditional silicon chargers when paired with standard cables?

FAQ: Sourcing & Technical Queries for Managers

Q: If I bundle a high-end usb type c charger with a standard cable, will it damage the battery?

A: No. The PD protocol is a "Pull" system, not a "Push" system. The device draws only what it needs, and the charger limits output based on cable capacity. The battery is safe, but charging speed will be capped at 60W (3A).

Q: Do your usbc chargers support "Cable Drop Compensation"?

A: Yes. Our designs typically include a compensation factor (e.g., 300mV max) to account for voltage loss across the cable length, ensuring the device receives the correct terminal voltage even with standard 1m or 2m cables.

Q: Why is PPS important for B2B charger procurement?

A: A pps charger allows the phone/laptop to communicate directly with the charger to request exact voltages. This reduces conversion heat inside the device, extending battery life. It is crucial for modern Samsung and Flagship devices.

Future Trends: Beyond the Cable

The future of the usb type c charger market is moving toward higher power density and smarter negotiation, necessitating even stricter cable requirements.

USB PD 3.1 & EPR (Extended Power Range): With the move to 240W (48V/5A), the distinction between standard and E-marked cables will become absolute. Chargers will simply refuse to output >60W without a verified EPR handshake.

Wireless integration: As cables become the bottleneck, we see a trend toward high-wattage wireless charging, though wired solutions remain king for efficiency.

Bio-based Cable Jackets: Sustainability is becoming a metric. We are testing chargers with cables using corn-based TPE to meet EU environmental standards without compromising thermal resistance.

Ready to Upgrade Your Power Lineup?

[Contact our Engineering Team] to discuss how Tommox’s GaN solutions can be customized for your specific market requirements, ensuring maximum compatibility and minimum return rates.

Understanding PPS (Programmable Power Supply): Why Your Phone Needs It

Understanding PPS (Programmable Power Supply): Why Your Phone Needs It