65W vs. 100W vs. 140W GaN Chargers: Which Is Best for Your Catalog?

03 Feb,2026

03 Feb,2026

In the rapidly evolving landscape of consumer electronics, selecting the right power delivery solution for your distribution network or brand portfolio is a complex engineering decision. While the market pushes for higher numbers, the 65 watt charger remains the volume king, balancing cost and performance, though the demand for the charger 100w and 140w charger segments is surging due to high-performance laptops.

As an engineer with a decade of experience in power topology and mass production, I have seen how marketing specs often clash with physical realities. This guide dissects the technical architecture, thermal constraints, and commercial viability of these three power tiers to help you make informed procurement decisions.

Technical Fundamentals: The Topology Shift

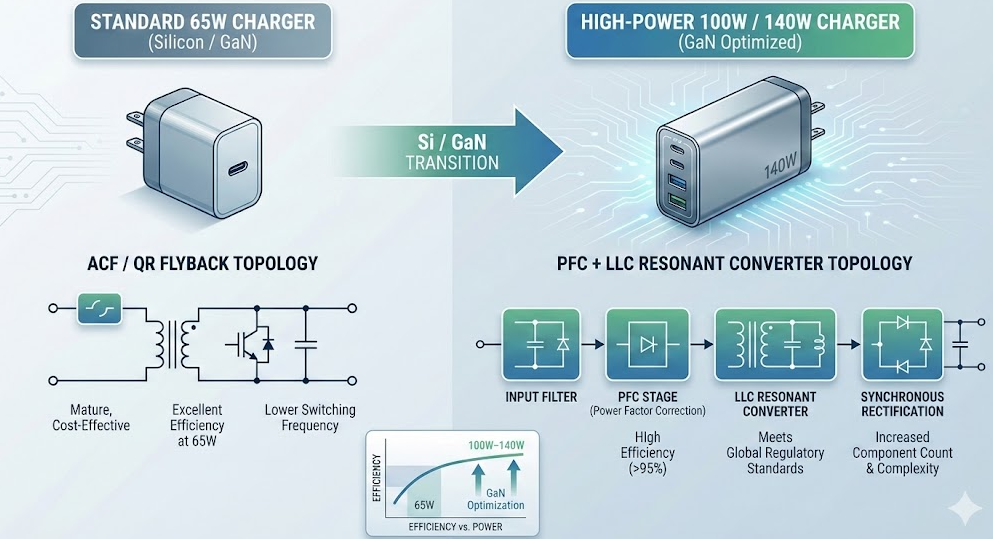

The transition from Silicon to Gallium Nitride (GaN) is not just about shrinking size; it is about switching frequency optimization. However, the circuit topology changes significantly as we move up the wattage ladder.

For a standard 65 watt charger, the industry standard is the Active Clamp Flyback (ACF) or Quasi-Resonant (QR) flyback topology. This architecture is mature, cost-effective, and offers excellent efficiency at this power level.

However, once you cross into the charger 100w and 140w charger territory, simple flyback topologies become inefficient due to higher switching losses and EMI challenges. Here, we must integrate PFC (Power Factor Correction) stages combined with LLC Resonant Converters. This adds component count and complexity but is necessary to meet global regulatory standards for power factor and efficiency.

Industry Pain Points in High-Density Power

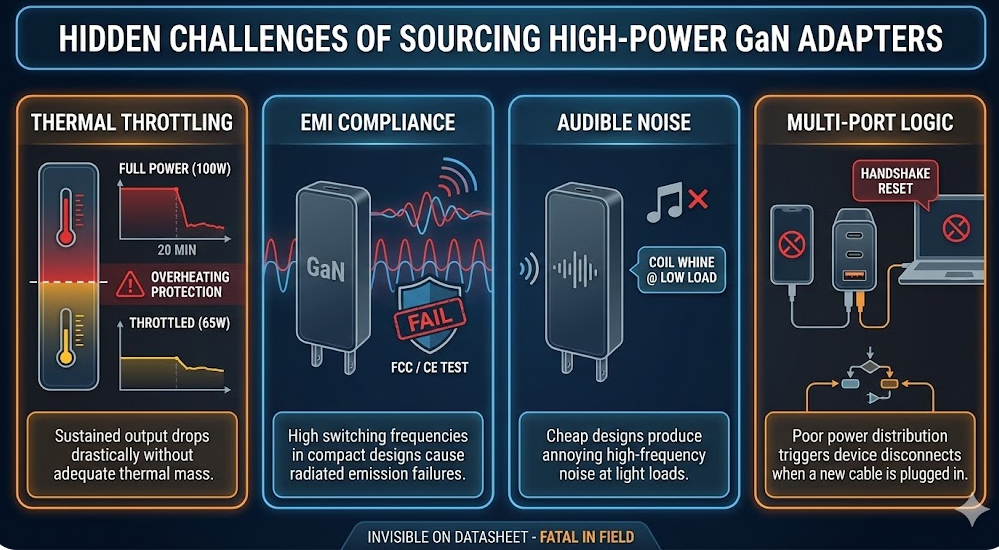

Sourcing high-power GaN adapters brings specific challenges that are often invisible on a datasheet but fatal in the field.

Thermal Throttling: Many ultra-slim chargers cannot sustain full power for more than 20 minutes. Without adequate thermal mass, the controller triggers protection modes, dropping a 100W output to 65W or lower.

EMI Compliance: Higher switching frequencies in compact spaces create significant Electromagnetic Interference. Poorly shielded designs will fail radiated emission tests (FCC/CE).

Audible Noise: In cheap 65 watt charger designs, coil whine at low loads (light load condition) is a common return reason.

Multi-Port Logic: Poor power distribution logic leads to devices disconnecting and reconnecting (handshake resets) whenever a new cable is plugged in.

Engineering Trade-off Analysis: Why Higher Isn't Always Better

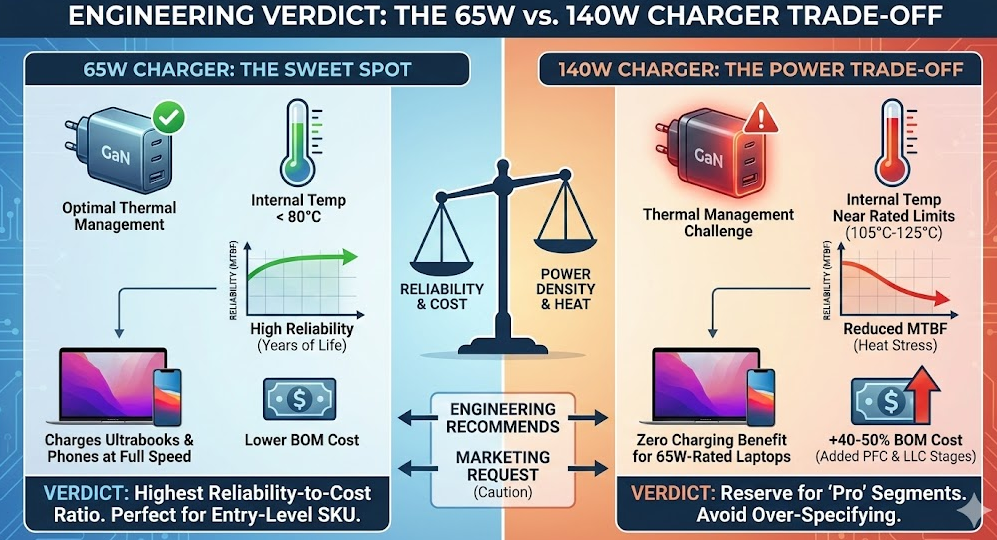

This is the most critical section for decision-makers. There is a prevalent misconception that a 140w charger is strictly "better" than a 65 watt charger. From an engineering standpoint, this is false; it is a trade-off between Power Density and Thermal Management.

In a strict engineering analysis, pushing 140W into a casing size similar to a 65W unit (a common marketing request) results in a drastically reduced MTBF (Mean Time Between Failures). To manage the heat generated by the PFC and LLC stages, the internal temperature of components often runs near their rated limits (105°C or 125°C).

Furthermore, for the vast majority of ultrabook and smartphone users, a 65 watt charger is the "sweet spot." It charges a MacBook Air or standard Dell XPS at full speed. Moving to a charger 100w increases the BOM cost by roughly 40-50% (due to the added PFC stage and more expensive GaN FETs) while offering zero charging speed benefit to a 65W-rated laptop.

The Engineering Verdict: Do not over-spec your entry-level SKU. The 65W unit offers the highest reliability-to-cost ratio. Reserve 100W and 140W SKUs specifically for "Pro" user segments who understand the size/weight penalty.

Comparison: 65 Watt Charger vs. 100W vs. 140W Architectures

To help you categorize your inventory, here is a technical breakdown of the three tiers:

1. The 65 Watt Charger (Volume Driver)

Target Device: Ultrabooks, Tablets, Smartphones.

Topology: QR Flyback or ACF (GaN).

Efficiency: ~93% peak.

Advantage: Lowest cost, smallest footprint, no PFC required (mostly).

Limitation: Insufficient for gaming laptops or high-end MacBook Pros under load.

2. The Charger 100W (Performance Tier)

Target Device: MacBook Pro 14", Performance Windows Laptops.

Topology: PFC + LLC (GaN).

Efficiency: ~94-95%.

Advantage: Universal compatibility for most office setups.

Limitation: Requires significantly better heat dissipation (glue filling recommended).

3. The 140W Charger (Cutting Edge)

Target Device: MacBook Pro 16", Mobile Workstations.

Topology: Interleaved PFC + LLC / AHB (Asymmetrical Half-Bridge).

Protocol: Requires PD 3.1 (Extended Power Range - EPR) to support 28V/5A.

Advantage: Fastest possible charging for flagship devices.

Limitation: High cost; requires specific EPR cables to function at full speed.

Tommox Design Philosophy & Implementation

At Tommox, we approach GaN design by prioritizing long-term reliability over achieving the absolute smallest cubic inch dimensions. Our engineering protocols for our OEM GaN charger solutions include:

Full Potting (Glue Filling): We inject a high-thermal-conductivity compound into the PCBA enclosure. This creates a solid block that dissipates heat evenly to the casing surface and improves drop-test survival rates.

Planar Transformers: For our charger 100w and 140W designs, we utilize planar transformers instead of wire-wound ones to reduce skin effect losses and height.

Ripple Control: We oversize output capacitors slightly to ensure low voltage ripple, protecting sensitive client device batteries.

Conservative Thermal Derating: We design our thermal envelopes to ensure the casing temperature remains compliant with IEC 62368-1 without aggressive throttling.

FAQ: Sourcing Manager Perspective

Q: Is a 140W charger backward compatible with a 65W device?

A: Yes. The PD 3.1 protocol is backward compatible.

Q: Why does the charger 100w sometimes pause when I plug in a second device?

A: This is "Dynamic Power Allocation." The controller must re-negotiate voltage and current contracts (PDOs) for both ports to prevent overcurrent. It is a safety feature, not a bug.

Q: Do I need PPS (Programmable Power Supply) for all models?

A: For a modern 65 watt charger catalog, PPS is mandatory to support Samsung Super Fast Charging. Without PPS, your product is not competitive in the Android market.

Future Trends & Design Direction

The future of power delivery lies in Power Density and Integration.

Integrated GaN ICs: Moving from discrete GaN FETs to "All-in-One" chips that combine the driver, FET, and protection logic will further reduce PCB footprint.

PD 3.1 Standardization: We expect the 28V (140W) and eventually 36V/48V (240W) standards to filter down from gaming laptops to standard high-performance notebooks.

Digital Control: Advanced MCUs will allow for firmware-updatable chargers that can adapt to new fast-charging protocols post-launch.

If you are looking to define your product roadmap for the next 12 months, starting with a robust, potting-filled 65 watt charger and a flagship 140w charger is the strategic move.

Would you like me to review your current charger specifications to identify potential thermal risks or cost-saving opportunities in your BOM?

Do GaN Chargers Work with Non-Fast Charging Cables? An Engineering Perspective

Do GaN Chargers Work with Non-Fast Charging Cables? An Engineering Perspective